Eco-Friendly Solutions

TUBE Technology

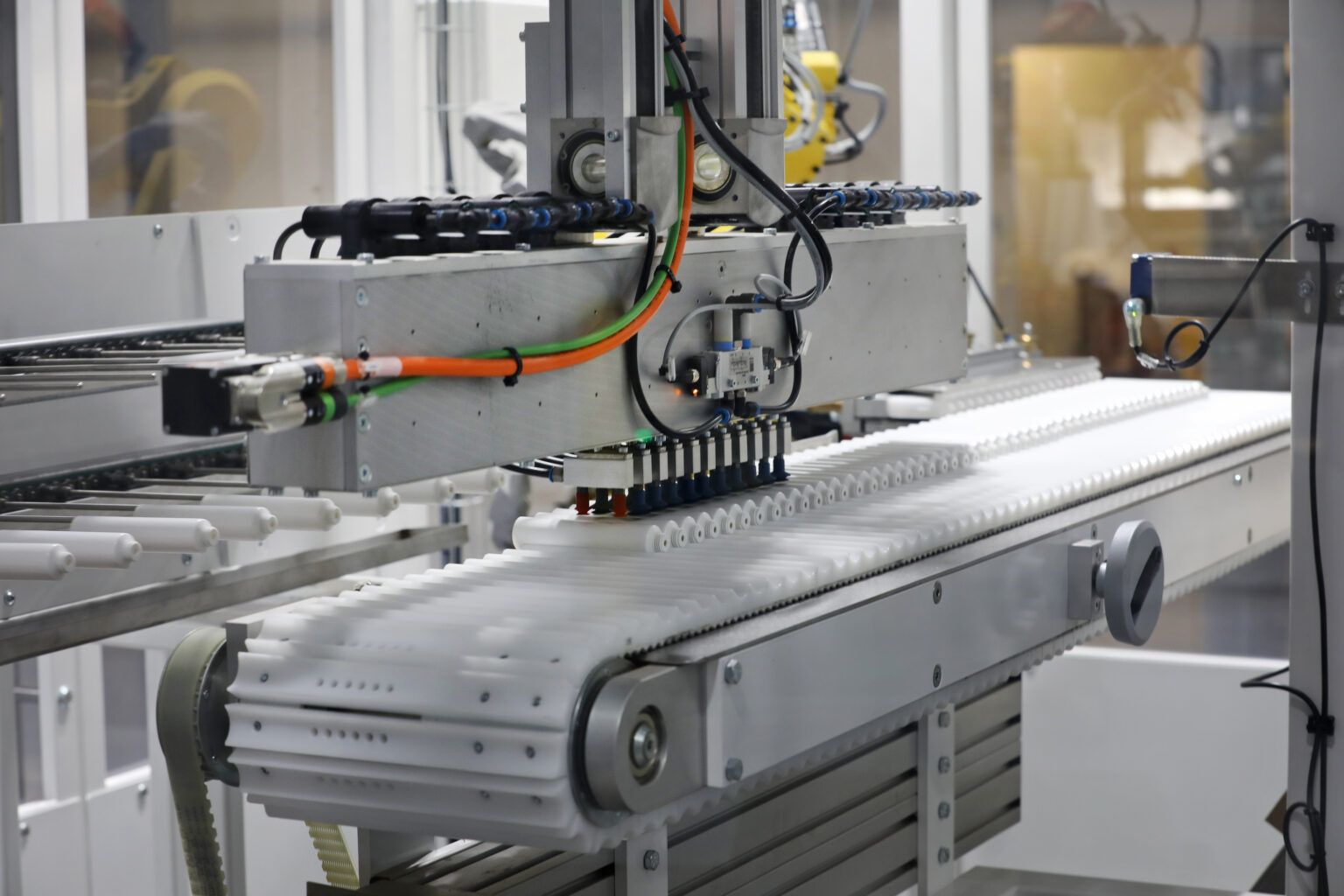

Axium’s latest innovation, an eco-friendly mono material tube with 100% HDPE sleeve, header and closure, simplifies the supply chain with in-house tube and closure manufacturing.

Capabilities

The vertical component manufacturing significantly shortens lead times, transitioning from weeks to days, courtesy of a state-of-the-art 7-layer high-speed extruder. This cutting-edge plastic tube extrusion and heading can manufacture tubes at an impressive rate of 240 parts per minute. By harnessing Axium’s expertise in closure, tube, decoration, and supply chain verticality, the finished premium plastic tubes exceed our customers evolving packaging requirements

Materials

- High-Density Polyethylene – HDPE

- Low-Density Polyethylene – LDPE

- Up to 100% HDPE PCR (Post Consumer Resin)

- EVOH (Ethylene-Vinyl Alcohol Copolymer) Barrier Resins

- Soft Touch Outer Layer

Markets Served

Personal Care

& Beauty

& Beauty

NEUTRACEUTICALS

HOUSEHOLD CHEMICAL

FOOD &

BEVERAGE

BEVERAGE

Healthcare

& OTC

& OTC

Expertly engineered tubes and closures for your business.

Tube Advantages

- Up to 100% PCR in monolayer tube sleeve and header

- Up to 88% PCR with virgin inner and outer tube

- In-house tube and closure manufacturing